+86 135 2793 7257

- Home

- Products

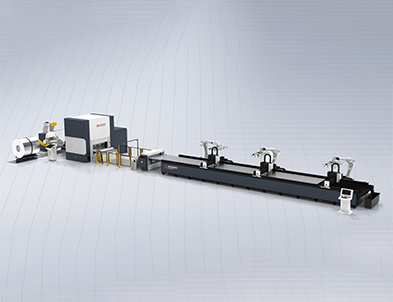

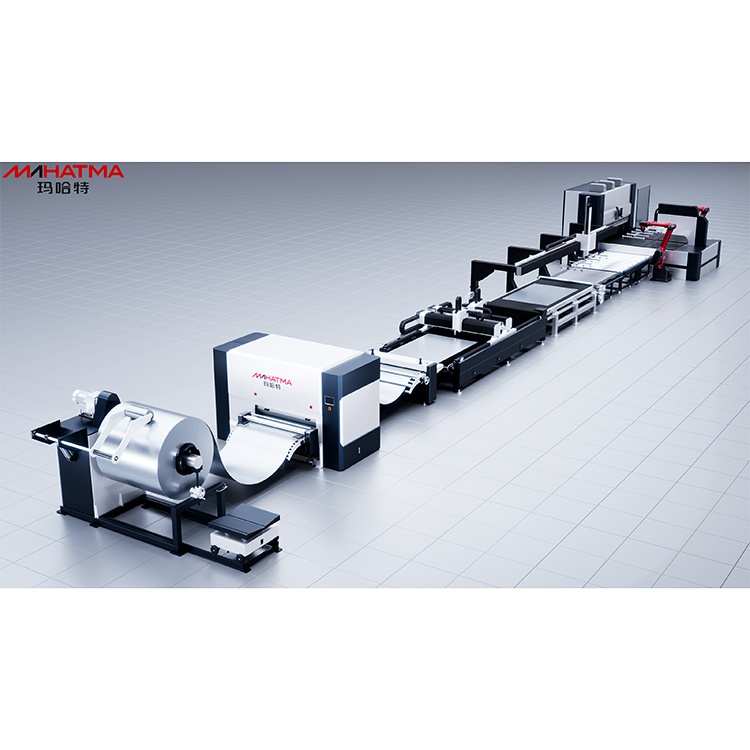

Reconstruct industrial machinery manufacturing related industries with new intelligent and ultra-corrective technologies

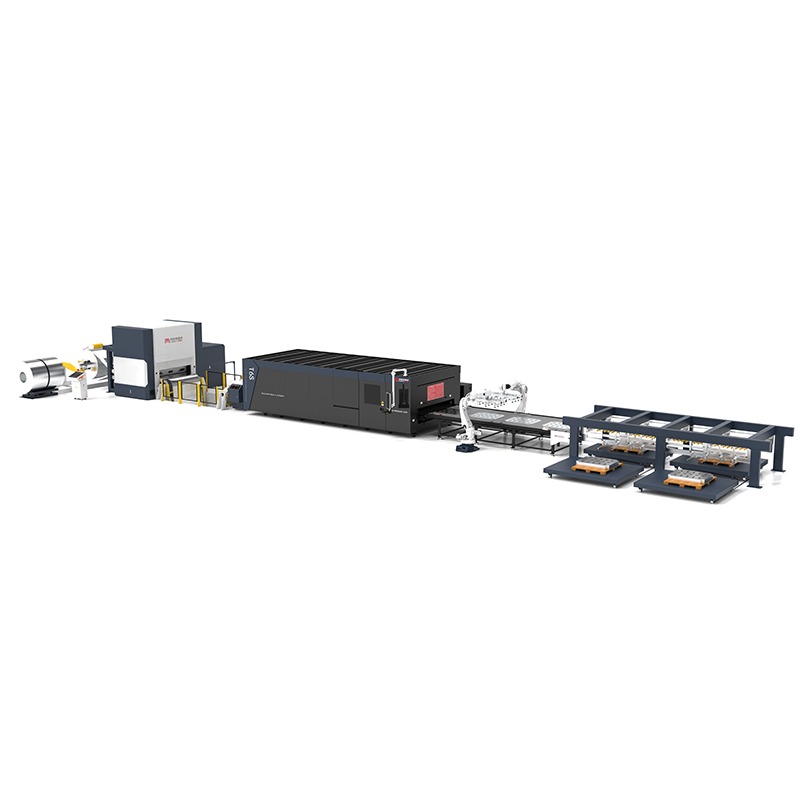

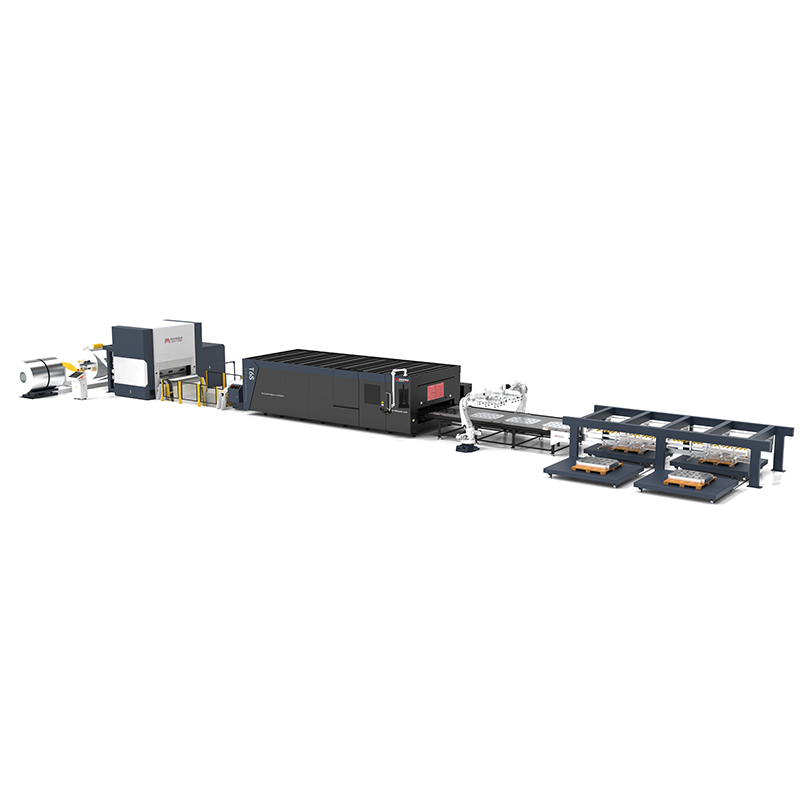

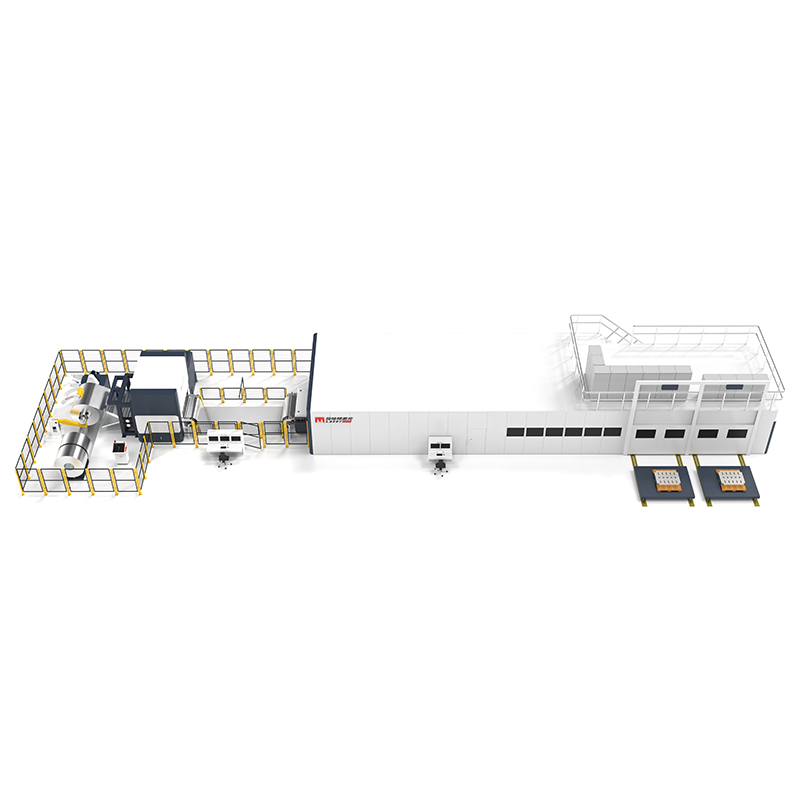

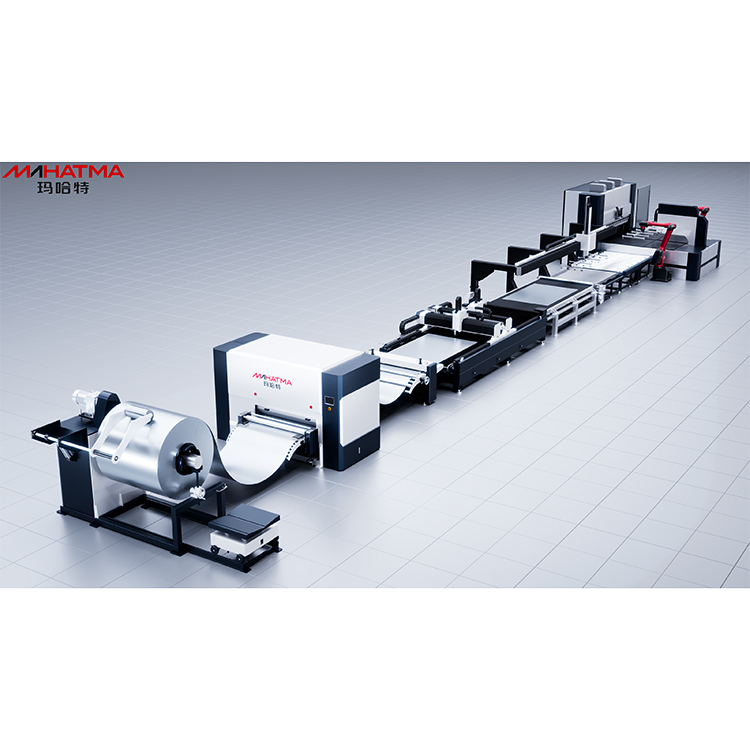

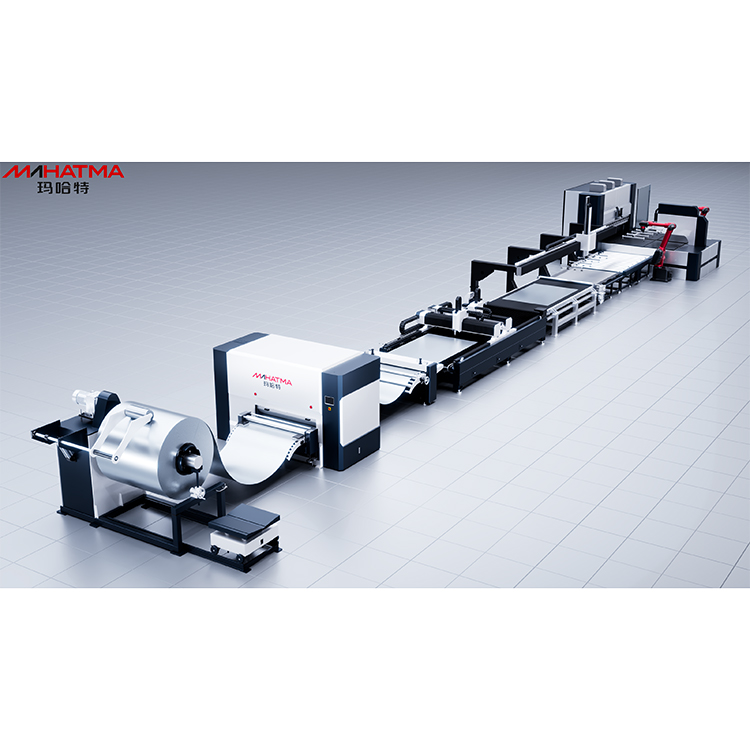

Reconstruct industrial machinery manufacturing related industries with new intelligent and ultra-corrective technologies Automated intelligent manufacturing, one-stop production line integration solution

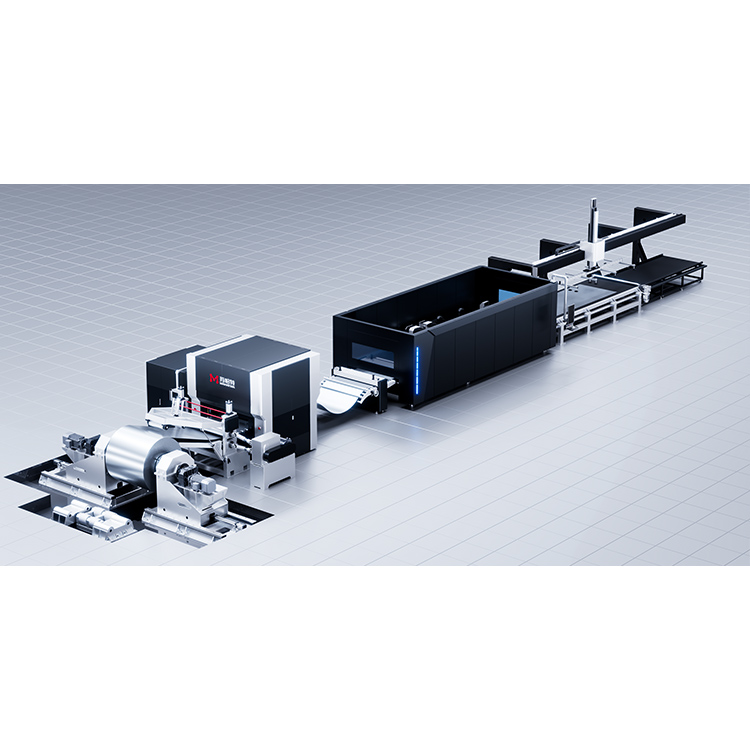

Automated intelligent manufacturing, one-stop production line integration solution Comprehensively master the advanced technology of high-end CNC leveling equipment

Comprehensively master the advanced technology of high-end CNC leveling equipment Customized optional equipment to create fully automatic industrial upgrades

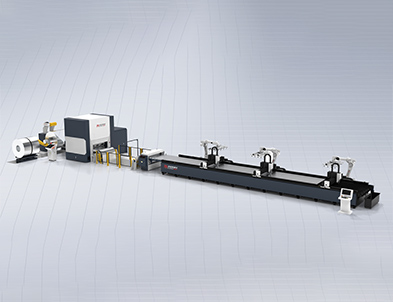

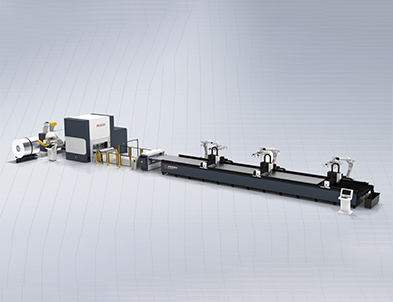

Customized optional equipment to create fully automatic industrial upgrades Small batch incoming sample leveling, the first choice for quality assurance of small and medium-sized enterprises

Small batch incoming sample leveling, the first choice for quality assurance of small and medium-sized enterprises Practical accessories make production more fluid

Practical accessories make production more fluid - Solutions

- About us

- Gallery

- News

- Contact

-

Language