In modern manufacturing, the demand for precision, speed, and automation has never been higher. Factories processing Sheet Metal, steel coils, and aluminum plates increasingly rely on advanced machinery to streamline operations and maintain competitive quality standards. Among these, the Automatic Laser Leveling Blanking Line has emerged as a game-changing solution, integrating laser cutting, automatic leveling, and feeding systems into a single production line. Manufacturers such as Laser Cutting Production Line Manufacturer provide solutions like Leveling Laser Cutting Machines and Leveling Laser Cutting Integrated Machines that combine high-speed processing with precision control. This article explores the key advantages of using an automatic laser leveling blanking line in modern factories, including efficiency, quality, safety, and cost-effectiveness.

1. Introduction to Automatic Laser Leveling Blanking Lines

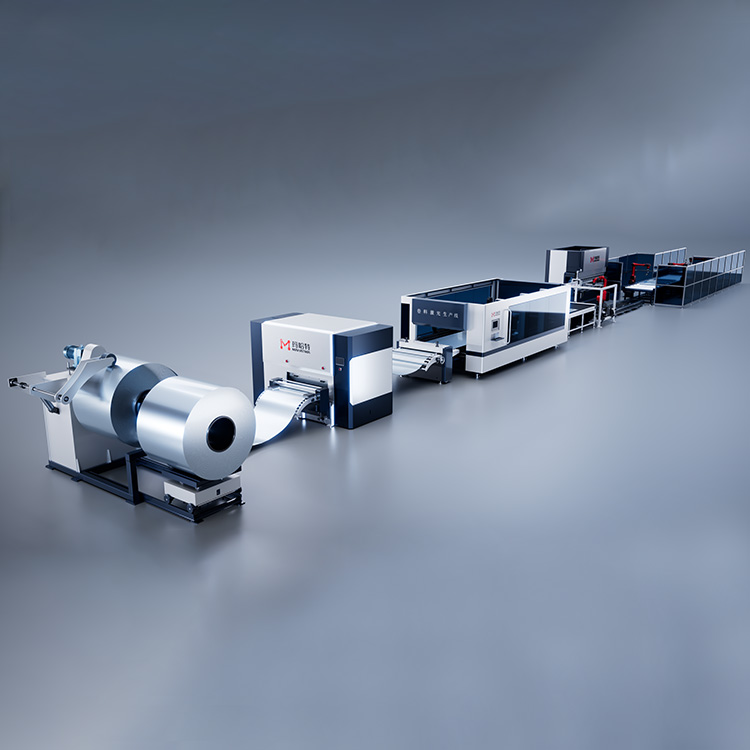

An Automatic Laser Leveling Blanking Line is a fully automated system designed for processing sheet metal from coils. It typically includes:

Coil Uncoiler: Automatically unwinds steel or aluminum coils.

Leveling Unit: Straightens the metal sheet, removing residual curvature or stress.

Laser Cutting System: Precisely blanks the sheet into desired shapes.

Conveyor and Stacking System: Collects and organizes the cut sheets.

This integrated system allows factories to handle high-volume Metal Processing with minimal manual labor, improving both throughput and product consistency.

2. High Precision and Quality

One of the most significant advantages of the Leveling Laser Cutting Machine is its ability to produce highly accurate cuts. Traditional mechanical shearing can cause slight deformations or edge burrs, especially with thicker metals. Laser cutting eliminates these issues by providing:

Clean Edges: Smooth, burr-free cuts without secondary processing.

High Dimensional Accuracy: Maintains tight tolerances essential for automotive, appliance, and electronics manufacturing.

Consistency Across Batches: Ensures all sheets from a coil meet the same quality standards.

By integrating leveling with cutting, the system guarantees that metal sheets are flat before laser processing, reducing errors and scrap.

3. Increased Productivity and Efficiency

Factories that adopt an Automatic Laser Leveling Blanking Line benefit from significantly improved efficiency:

Continuous Operation: Automated uncoiling, leveling, and cutting reduces downtime and speeds up production.

High-Speed Processing: Advanced laser systems can cut sheets rapidly, even in high-strength metals.

Reduced Manual Labor: Minimal operator intervention allows staff to focus on quality control and other tasks.

Optimized Material Usage: Laser cutting minimizes waste by allowing precise nesting of patterns on the sheet.

This combination of speed and automation helps factories meet tight deadlines while maintaining output consistency.

4. Versatility and Adaptability

Modern Leveling Laser Cutting Integrated Machines can handle a variety of materials and thicknesses, including:

Stainless steel

Mild steel

Aluminum

Galvanized sheets

Additionally, the system can be programmed for different sheet sizes and blanking patterns, making it suitable for multiple production lines without extensive reconfiguration. This versatility is particularly valuable for factories producing components for diverse industries, from automotive panels to appliance parts.

5. Safety and Reduced Labor Risks

Automated laser leveling and cutting systems improve workplace safety in several ways:

Reduced Manual Handling: Operators no longer need to manually feed or cut heavy metal coils.

Laser Safety Enclosures: Cutting areas are fully enclosed to prevent accidental exposure to laser beams.

Automated Error Detection: Modern systems can detect misfeeds or jams and stop automatically, preventing accidents.

By reducing human intervention in potentially dangerous processes, factories can maintain a safer working environment while still achieving high productivity.

6. Integration with Smart Manufacturing

Many Laser Cutting Production Line Manufacturers now offer integrated systems compatible with Industry 4.0 smart factory concepts. Benefits include:

Real-Time Monitoring: Track production progress, laser status, and system diagnostics.

Predictive Maintenance: Sensors monitor wear and tear, scheduling maintenance before failures occur.

Data-Driven Optimization: Production data can be analyzed to improve cutting patterns, minimize material waste, and maximize throughput.

This level of integration ensures that the Leveling Laser Cutting Integrated Machine fits seamlessly into modern automated factories.

7. Cost-Effectiveness Over Time

Although the initial investment in an Automatic Laser Leveling Blanking Line can be substantial, the long-term benefits outweigh costs:

Reduced Labor Costs: Automation reduces the need for large workforces.

Lower Material Waste: Precision laser cutting and leveling minimize scrap.

Maintenance Savings: Modern machines are designed for low maintenance with long-lasting components.

Increased Output: Higher throughput translates to faster ROI.

Factories adopting these integrated machines often see measurable savings within the first few years of operation.

8. Applications Across Industries

The Automatic Laser Leveling Blanking Line is used in multiple sectors:

Automotive: Body panels, chassis components, and brackets.

Home Appliances: Washing machines, refrigerators, ovens, and panels.

Electronics: Enclosures, frames, and structural metal parts.

Furniture: Metal components for chairs, tables, and shelving systems.

Construction and Architecture: Metal panels for facades and structures.

In each case, the system ensures consistent quality, fast production, and minimal waste, making it an invaluable asset in modern metalworking facilities.

9. Choosing the Right System for Your Factory

Selecting the ideal Automatic Laser Leveling Blanking Line involves evaluating:

Material Compatibility: Ensure the system handles the types and thicknesses of metal your factory uses.

Production Volume: Match the machine’s capacity with your required throughput.

Automation Level: Decide between semi-automated or fully integrated systems.

Manufacturer Support: Reliable after-sales service and training are essential for long-term operation.

Optional Features: Consider additional features like nesting software, stacking automation, or remote monitoring.

Consulting with reputable Laser Cutting Production Line Manufacturers ensures you choose a system that fits both your technical requirements and budget.

10. Future Trends in Laser Leveling and Blanking Technology

The industry continues to evolve with innovations in laser power, automation, and smart factory integration:

Higher-Power Lasers: Capable of cutting thicker metals at higher speeds.

Compact Integrated Lines: Smaller footprints for factories with limited space.

IoT Integration: Remote monitoring, predictive maintenance, and data analytics.

Hybrid Systems: Combining laser cutting with bending, punching, or forming in one automated line.

Energy Efficiency: Machines designed to minimize electricity consumption while maximizing output.

These trends suggest that Leveling Laser Cutting Machines and Leveling Laser Cutting Integrated Machines will become even more vital in competitive manufacturing environments.

Conclusion

The Automatic Laser Leveling Blanking Line offers factories a combination of precision, efficiency, automation, and safety. By integrating Laser Cutting, coil leveling, and automatic feeding into a single line, manufacturers can achieve high-quality sheet metal production with minimal waste and reduced labor costs.

Whether using a Leveling Laser Cutting Machine, an Integrated Laser Cutting System, or a fully automated production line from a trusted Laser Cutting Production Line Manufacturer, modern factories benefit from faster production, consistent quality, and long-term cost savings.

Adopting these systems positions manufacturers at the forefront of modern industrial automation, ensuring competitiveness, scalability, and readiness for future manufacturing innovations.