In modern manufacturing, efficiency, precision, and automation are crucial. Industries such as automotive, appliance production, and metal fabrication increasingly rely on advanced equipment to optimize operations. Among the most essential technologies for handling Sheet Metal efficiently is the uncoiling laser blanking production line. This type of system integrates laser uncoiling, laser blanking, and sometimes coil leveling and automatic feeding to streamline the processing of steel coils and other metal materials. In this article, we will explore how to select the right production line for your factory, discussing technical specifications, applications, advantages, and key considerations. Keywords such as Laser blanking, Laser Uncoiling, Laser Coil Leveling Automatic Feeding Line, Laser Uncoiling and Blanking Line, and Steel Coil Leveling Laser Production Line are naturally integrated throughout.

1. Understanding the Basics of an Uncoiling Laser Blanking Production Line

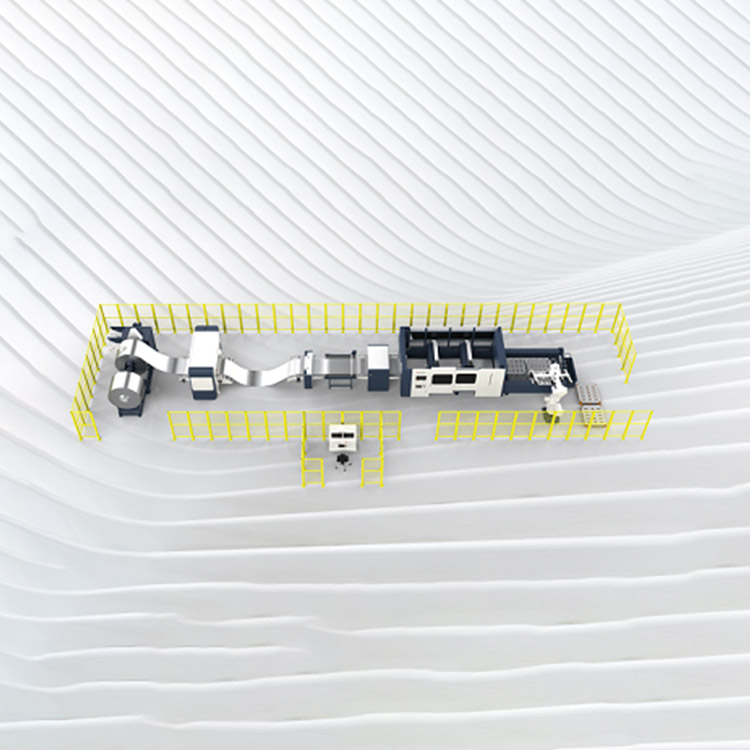

A Laser Uncoiling and Blanking Line is a high-tech solution designed to automate the process of uncoiling metal strips from coils, leveling them if necessary, and cutting them into precise sheets using laser technology. This combination of processes reduces manual labor, minimizes material waste, and ensures high precision.

Key components include:

Coil Uncoiler: Automatically unwinds the steel coil for continuous processing.

Laser Coil Leveling Automatic Feeding Line: Ensures flat, straight sheets by leveling the metal as it moves through the system.

Laser Blanking Unit: Uses high-precision lasers to cut metal sheets to exact dimensions.

Stacking or Conveying System: Organizes finished sheets for easy handling and storage.

By integrating these elements, a Steel Coil Leveling Laser Production Line enhances production efficiency and maintains consistent quality.

2. Key Advantages of Laser-Based Uncoiling and Blanking

Choosing a Laser Uncoiling and Blanking Line offers several advantages over traditional mechanical cutting methods:

High Precision: Laser technology provides accurate cuts, with minimal deviation even on complex shapes.

Reduced Material Waste: The precision of laser blanking ensures optimal use of sheet metal.

Automation and Efficiency: Integrated uncoiling, leveling, and feeding lines reduce manual intervention, increasing throughput.

Flexibility: Laser systems can handle a wide range of steel thicknesses and coil widths.

Improved Safety: Automation reduces the need for operators to manually handle heavy steel coils.

These benefits make Laser Uncoiling and Blanking Lines an ideal choice for factories aiming to boost productivity and quality.

3. Applications of Uncoiling Laser Blanking Production Lines

Laser Uncoiling and Blanking Lines are widely applied across industries requiring precision sheet Metal Processing. Typical applications include:

Automotive Manufacturing: Producing chassis components, body panels, and brackets with high precision.

Home Appliances: Cutting metal sheets for washing machines, refrigerators, and ovens.

Electrical Enclosures: Fabricating panels for cabinets, switchgear, and transformers.

Furniture Manufacturing: Producing metal components for office furniture and shelving.

General Metal Fabrication: Cutting steel or aluminum sheets for various industrial uses.

A Steel Coil Leveling Laser Production Line allows manufacturers to handle high volumes of sheet metal efficiently while maintaining consistent quality.

4. Factors to Consider When Choosing the Right Production Line

Selecting the right Laser Coil Leveling Automatic Feeding Line involves evaluating several key factors to ensure it meets your factory’s production needs:

4.1 Material Specifications

Thickness Range: Verify that the system supports the thickness of the metal coils you plan to process.

Coil Width: Ensure the uncoiler and leveling line accommodate your coil widths.

Material Type: Confirm compatibility with steel, stainless steel, aluminum, or other alloys.

4.2 Production Capacity

Throughput: Consider sheets per hour or tonnage per day to match your production goals.

Cutting Speed: High-speed laser blanking units increase efficiency without sacrificing accuracy.

4.3 Automation and Integration

Laser Uncoiling systems with automatic feeding reduce operator intervention.

Integration with leveling, blanking, and stacking systems improves workflow.

Compatibility with factory automation systems allows for real-time monitoring and control.

4.4 Precision and Quality

Laser spot size and cutting power affect accuracy and edge quality.

Check the system’s ability to maintain flatness and dimensional consistency.

4.5 Maintenance and Reliability

Evaluate the reliability of the laser source, rollers, bearings, and conveyor systems.

Consider the ease of maintenance, availability of replacement parts, and technical support from the manufacturer.

4.6 Safety Features

Emergency stop systems, protective covers, and laser shielding ensure safe operation.

Automated coil handling reduces risk of injury from manual intervention.

5. Comparing Different Types of Lines

There are several configurations of uncoiling laser blanking production lines, each suited to specific needs:

Basic Laser Uncoiling and Blanking Line: Focuses on uncoiling and cutting without leveling. Suitable for applications where flatness is not critical.

Laser Coil Leveling Automatic Feeding Line: Adds Precision Leveling before cutting, ideal for high-quality sheet production.

Integrated Steel Coil Leveling Laser Production Line: Fully automated system with uncoiling, leveling, laser blanking, and stacking for maximum efficiency.

Factories with high-volume, high-precision requirements typically benefit most from the fully integrated Steel Coil Leveling Laser Production Line.

6. Cost Considerations

While laser uncoiling and blanking lines involve higher initial investment compared to mechanical cutting, the long-term benefits often justify the cost:

Reduced Labor Costs: Automation minimizes manual handling and increases output.

Material Savings: Precision laser blanking reduces scrap.

Increased Production Speed: High-speed cutting increases throughput.

Lower Maintenance Costs: Fewer mechanical parts wear out compared to traditional systems.

A cost-benefit analysis should consider production volume, quality requirements, and return on investment (ROI).

7. Installation and Operator Training

Proper installation and staff training are critical for optimal performance:

Ensure alignment of the uncoiler, leveling rollers, and laser unit.

Train operators on system operation, safety procedures, and basic troubleshooting.

Implement preventive maintenance schedules to maximize uptime.

A well-trained team ensures the Laser Uncoiling and Blanking Line operates at peak efficiency.

8. Future Trends in Laser Uncoiling and Blanking

Technological advancements continue to shape the development of uncoiling laser blanking production lines:

Higher-Power Lasers: Enable faster cutting of thicker materials.

Smart Factory Integration: IoT-enabled lines provide real-time monitoring, predictive maintenance, and remote control.

Energy Efficiency: Newer systems consume less power while maintaining high throughput.

Hybrid Systems: Combining laser cutting with punching or bending for more versatile operations.

These trends ensure that Laser Coil Leveling Automatic Feeding Lines remain a critical investment for modern factories.

Conclusion

Choosing the right uncoiling laser blanking production line is essential for factories aiming to enhance precision, efficiency, and automation in sheet metal processing. Evaluating material specifications, production capacity, automation, precision, safety, and maintenance requirements ensures that the chosen line meets current and future manufacturing needs.

Whether it’s a Laser Uncoiling and Blanking Line, a Laser Coil Leveling Automatic Feeding Line, or a fully integrated Steel Coil Leveling Laser Production Line, investing in advanced laser technology enables manufacturers to optimize productivity, reduce waste, and maintain consistent high-quality output.

With proper selection, installation, and maintenance, these advanced production lines provide a reliable and long-term solution for modern sheet metal processing, positioning your factory for success in competitive markets.