In today’s highly competitive manufacturing environment, efficiency, quality, and cost control are key factors for business success. Traditional inspection methods, relying heavily on manual labor, often result in slower production, higher error rates, and increased operational costs. The integration of automation into inspection processes, particularly through a Leveling Inspection Production Line, has emerged as a critical solution for modern manufacturers. When implemented within a smart factory environment, part of smart manufacturing industry 4.0, these systems deliver significant cost-saving benefits while enhancing product quality and operational efficiency.

This article explores the financial and operational advantages of automating inspection using a leveling Production Line, demonstrating how manufacturers can leverage smart factory 4.0 principles to optimize their processes.

Understanding the Leveling Inspection Production Line

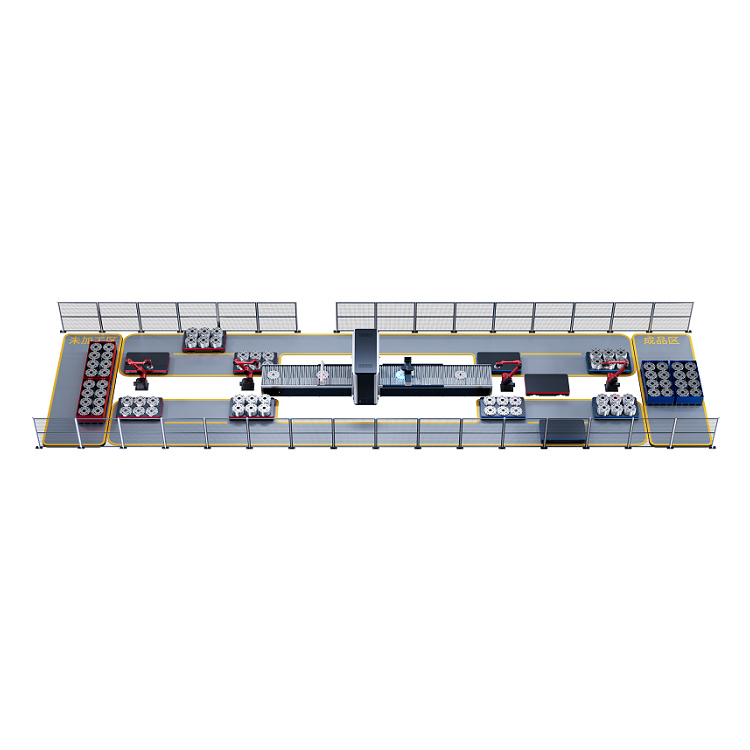

A leveling Inspection Production Line is designed to automate the inspection of metal sheets, coils, or strips, ensuring that products meet precise dimensional and surface quality standards. Traditionally, inspection tasks were performed manually, which was time-consuming and prone to errors. Automation integrates advanced sensors, cameras, and real-time monitoring systems to streamline inspection processes, detect defects immediately, and maintain consistent product quality.

In a smart factory 4.0, this production line is connected with other digital systems, including production scheduling, data analytics, and machine learning algorithms. This integration not only ensures accurate inspection but also provides actionable insights for improving production efficiency and reducing costs.

Reduced Labor Costs

One of the most immediate cost-saving benefits of automating inspection is a reduction in labor expenses. Manual inspection requires skilled personnel to measure, detect, and record defects, often resulting in high labor costs and slower throughput.

Automation Efficiency: Automated inspection systems can operate continuously without fatigue, reducing the need for large inspection teams.

Reallocation of Workforce: Skilled personnel can be reassigned to value-added tasks such as production optimization, maintenance, or system monitoring.

Minimized Human Error: Automation ensures consistency and precision, reducing the costs associated with defects caused by manual inspection mistakes.

By implementing a Leveling Inspection Production Line in a smart factory, manufacturers achieve not only lower labor costs but also more consistent and reliable inspection results.

Increased Production Throughput

Automated inspection systems significantly enhance production throughput by reducing bottlenecks and eliminating delays associated with manual checks:

Real-Time Inspection: Advanced cameras and sensors evaluate each sheet or coil instantly, allowing continuous production without pauses.

Integrated Feedback Systems: Defective materials are automatically flagged and removed from the production line, preventing downstream delays.

Optimized Workflow: Data collected during inspection can be used to adjust upstream processes, ensuring smoother operations.

Higher throughput translates to more units produced per hour, directly contributing to cost savings and higher revenue potential.

Reduced Material Waste

Material waste is a significant cost factor in manufacturing, especially when defects are discovered late in the production process. Automated inspection on a Leveling Production Line reduces waste in multiple ways:

Early Defect Detection: Defects in flatness, thickness, or surface quality are detected immediately, preventing further processing of unusable material.

Precision Flattening and Leveling: Integration with leveling systems ensures that sheets and coils meet exact specifications before downstream processing.

Data-Driven Optimization: Historical inspection data helps optimize material usage, minimizing scrap and rework.

By reducing waste, manufacturers can achieve substantial cost reductions in raw materials and improve sustainability, aligning with smart manufacturing industry 4.0 goals.

Lower Maintenance and Operational Costs

Automating inspection also reduces maintenance and operational costs:

Predictive Maintenance: Smart sensors monitor equipment condition and alert operators to potential issues before breakdowns occur, avoiding expensive downtime.

Reduced Rework: Early defect detection prevents defective products from entering downstream processes, saving labor and material costs associated with rework.

Energy Efficiency: Automated inspection systems in a smart factory 4.0 optimize power consumption by controlling motors, sensors, and conveyors intelligently.

These factors collectively lower the total cost of ownership for production lines, contributing to long-term savings.

Enhanced Product Quality and Customer Satisfaction

High-quality products reduce warranty claims, returns, and rework costs. Automated inspection ensures consistent quality across all units:

Consistent Standards: Automated leveling and inspection maintain tight tolerances and uniform surface quality.

Real-Time Quality Feedback: Operators can immediately correct deviations in upstream processes based on inspection results.

Data-Driven Improvement: Analysis of inspection data supports continuous improvement initiatives, ensuring long-term quality enhancements.

Superior product quality not only reduces costs but also enhances customer satisfaction and strengthens brand reputation, creating indirect financial benefits.

Integration with Smart Factory Systems

Implementing a Leveling Inspection Production Line within a smart factory environment amplifies cost-saving benefits:

Seamless Data Connectivity: Inspection data is integrated with production planning, ERP systems, and other automation systems for holistic operational control.

Predictive Analytics: Machine learning algorithms analyze inspection data to forecast potential defects, enabling proactive interventions.

End-to-End Automation: Integration with leveling, bending, or coating lines ensures that defective materials are automatically corrected or removed, reducing manual intervention.

By leveraging smart manufacturing industry 4.0 capabilities, manufacturers can optimize the entire production chain, reducing costs and improving operational efficiency.

Flexibility and Scalability

Automated inspection systems offer flexibility that traditional manual methods cannot match:

Adaptable to Different Materials: Inspection systems can handle various metal types, thicknesses, and surface finishes without extensive reconfiguration.

Scalable Production: Lines can be expanded or integrated with additional automated processes as production demands grow.

Quick Changeover: Automated systems can adjust inspection parameters rapidly for different product types, reducing downtime.

Flexibility ensures that manufacturers can respond quickly to changing market demands without incurring excessive costs.

Safety and Workforce Benefits

Automation also improves workplace safety, indirectly contributing to cost savings:

Reduced Human Exposure: Operators are no longer required to manually inspect heavy or sharp metal sheets, minimizing the risk of injury.

Focus on High-Value Tasks: Employees are redeployed to supervisory, maintenance, or data analysis roles, enhancing overall productivity.

Compliance with Safety Standards: Automated systems help meet regulatory requirements, avoiding potential fines or operational interruptions.

Lower accident rates and safer workplaces reduce insurance costs and contribute to long-term operational savings.

Environmental and Sustainability Benefits

Reducing material waste and optimizing energy use also provides environmental and financial benefits:

Energy Savings: Automated inspection systems are optimized to consume minimal power.

Material Efficiency: Fewer defects mean less scrap, reducing both raw material costs and environmental impact.

Sustainable Manufacturing: Data-driven production supports greener practices, aligning with corporate sustainability goals.

These benefits reinforce the economic and ecological advantages of integrating smart factory 4.0 solutions.

Conclusion

Automating inspection with a Leveling Inspection Production Line offers substantial cost-saving benefits for manufacturers. By reducing labor costs, minimizing material waste, enhancing product quality, improving operational efficiency, and integrating with smart factory technologies, companies can achieve a significant return on investment.

The adoption of smart manufacturing industry 4.0 practices ensures that inspection is not just faster and more accurate but also seamlessly integrated into the broader production ecosystem. Manufacturers who implement smart factory 4.0 solutions can reduce operational costs, increase throughput, and maintain competitive advantage in an increasingly challenging market.

Investing in automation for inspection processes is no longer optional—it is a strategic necessity for companies looking to optimize production, save costs, and maintain high-quality standards in the era of Industry 4.0.