In today’s competitive manufacturing environment, companies are under immense pressure to increase efficiency, reduce costs, and maintain consistently high product quality. The emergence of smart factory technologies, part of Industry 4.0, has transformed traditional production systems by integrating automation, data analytics, and intelligent digital control. Also referred to as a smart factory 4.0 or smart factory industry 4.0, these modern facilities enable manufacturers to optimize operations, minimize errors, and improve overall production flexibility.

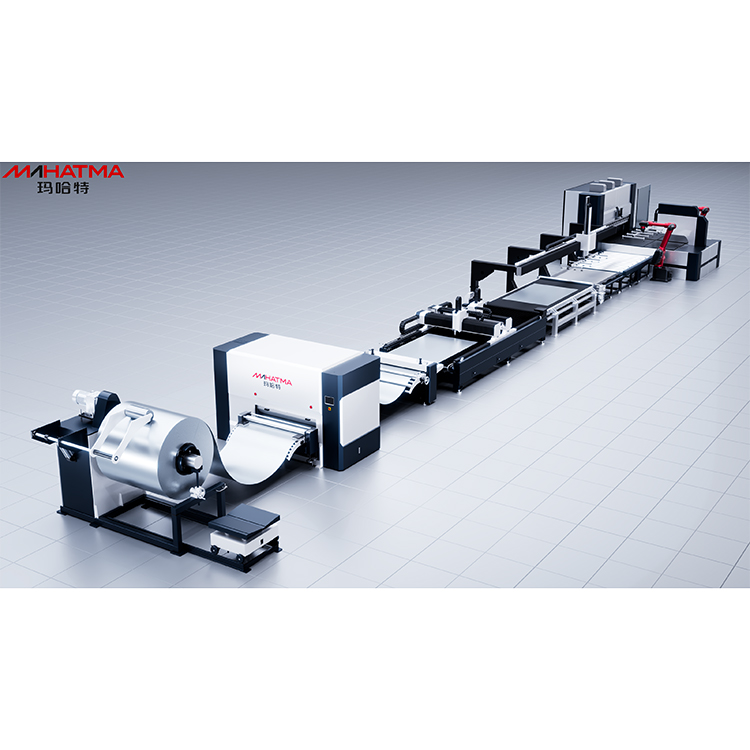

One excellent example of how a smart factory can transform production is the Automatic Unwinding, Flattening and Bending Line, which automates multiple critical metalworking processes. By implementing such systems in a smart manufacturing environment, companies can achieve higher throughput, lower operational costs, and superior product quality. This article explores the benefits of adopting an automated production line like this within a smart factory 4.0 framework.

Understanding the Automatic unwinding, flattening and bending line

The Automatic unwinding, Flattening and Bending Line is designed to handle metal coils, wire, or strips, automating the processes of unwinding raw material, flattening it to precise tolerances, and bending it into the required shape. Traditionally, these tasks involved multiple manual operations, which were labor-intensive, time-consuming, and prone to errors.

In a smart factory industry 4.0, this production line is integrated with intelligent systems that communicate in real time, monitor production parameters, and adapt operations automatically. Sensors, IoT devices, and advanced control software enable manufacturers to precisely manage coil feeding, flattening pressure, and bending angles, ensuring consistency and efficiency across every batch.

Increased Production Efficiency

Implementing an Automatic Unwinding, Flattening and Bending Line in a smart factory significantly boosts production efficiency:

Continuous Operation: The line can operate continuously, handling high-volume production without interruptions or fatigue, unlike manual labor.

Optimized Workflow: Integrated software systems schedule production, coordinate coil feeding, flattening, and bending operations, and reduce bottlenecks.

Reduced Setup Time: Automatic adjustment of bending angles and flattening parameters allows for quick changeovers between different product specifications.

By leveraging these capabilities, a smart factory 4.0 can produce more parts per hour with minimal downtime, ensuring higher throughput and faster order fulfillment.

Reduced Human Errors

Human error is a major source of defects in traditional Metal Processing operations. By incorporating the Automatic Unwinding, Flattening and Bending Line into a smart manufacturing environment, errors are significantly reduced:

Automated Material Handling: The line automatically unwinds, flattens, and bends material according to programmed specifications, eliminating inconsistencies caused by manual handling.

Precision Monitoring: Sensors and feedback systems continuously check material thickness, bending angles, and flattening tolerances, ensuring accurate production.

Predictive Alerts: The system can detect potential malfunctions or deviations and alert operators before quality issues occur.

This automation ensures higher-quality outputs, reduces waste, and minimizes the need for costly rework.

Cost Reduction and Resource Optimization

Integrating an Automatic Unwinding, Flattening and Bending Line into a smart factory industry 4.0 setup can lower operational costs and optimize resource utilization:

Labor Savings: Automation reduces dependency on manual labor for repetitive processes, allowing workers to focus on supervisory and value-added tasks.

Material Efficiency: Precise control of flattening pressure and bending angles reduces material scrap and maximizes the use of raw materials.

Energy Optimization: Smart control systems manage motors and hydraulic pressure efficiently, minimizing energy consumption.

Reduced Downtime: Predictive maintenance features monitor line components and schedule preventive maintenance, avoiding unexpected stoppages.

By minimizing waste, energy use, and labor costs, a smart factory 4.0 delivers a better return on investment and more sustainable operations.

Enhanced Product Quality

A primary advantage of implementing the Automatic Unwinding, Flattening and Bending Line within a smart factory is improved product quality:

Consistency and Precision: Automated flattening and bending processes maintain tight tolerances, ensuring uniformity across all produced parts.

Real-Time Monitoring: Sensors track material dimensions and bending angles in real time, enabling immediate corrections if deviations occur.

Data Analytics for Improvement: Historical production data can be analyzed to optimize line parameters and reduce defects over time.

This level of precision ensures that products meet stringent industrial standards, enhancing customer satisfaction and brand reputation.

Flexibility and Customization

Modern manufacturing requires flexibility to adapt to different product types and batch sizes. A smart factory 4.0 equipped with an Automatic Unwinding, Flattening and Bending Line offers high adaptability:

Quick Changeover: Programmable settings allow the line to handle different material sizes, thicknesses, and bending requirements efficiently.

Mass Customization: The system can produce customized components without compromising speed or quality.

Scalability: The line can be integrated with other automated production systems to expand capacity as needed.

This flexibility allows manufacturers to respond quickly to customer demands and market fluctuations, maintaining competitiveness in the smart manufacturing era.

Data-Driven Decision Making

In a smart factory industry 4.0, data is crucial for optimizing production:

Performance Analytics: Sensors collect real-time data on line speed, bending accuracy, and material usage, allowing managers to make informed decisions.

Predictive Maintenance: AI and machine learning analyze equipment performance data to forecast maintenance needs and prevent downtime.

Continuous Improvement: Historical production insights identify inefficiencies and inform process optimizations.

Leveraging data ensures that production is efficient, reliable, and continuously improving.

Safety and Workforce Empowerment

Automation of high-risk processes, such as metal handling and bending, enhances workplace safety:

Hazard Reduction: Robots and automated systems handle heavy and dangerous materials, reducing the risk of accidents.

Remote Monitoring: Operators can oversee line performance from a safe distance, minimizing exposure to potentially hazardous operations.

Workforce Upskilling: Employees focus on supervising, programming, and optimizing the line rather than performing repetitive manual labor, boosting skills and engagement.

By improving safety and workforce efficiency, smart manufacturing creates a productive and empowered team environment.

Environmental Sustainability

Many smart factory 4.0 initiatives focus on sustainable production practices:

Energy Efficiency: Automated line controls optimize motor and hydraulic system usage.

Material Waste Reduction: Precision flattening and bending minimize scrap and support recycling initiatives.

Sustainable Operations: Data-driven monitoring ensures efficient use of raw materials and energy, contributing to greener manufacturing.

The Automatic Unwinding, Flattening and Bending Line not only improves efficiency but also supports environmentally responsible manufacturing practices.

Conclusion

The implementation of an Automatic Unwinding, Flattening and Bending Line within a smart factory delivers significant advantages, including higher production efficiency, reduced human errors, lower operational costs, enhanced product quality, flexible production, data-driven decision-making, improved safety, and environmental sustainability.

By adopting smart manufacturing principles and embracing smart factory 4.0 technologies, manufacturers can transform traditional metalworking operations into highly automated, agile, and efficient systems. This modernization ensures that businesses remain competitive in the fast-evolving smart factory industry 4.0, meet growing customer demands, and achieve long-term profitability.