In the field of modern metal fabrication, surface precision and flatness are essential for product quality. Uneven, wavy, or warped plates can cause assembly problems, reduce structural integrity, and increase processing costs. To address these challenges, the Hydraulic leveling machine—also known simply as a leveling machine—has become an indispensable tool in industries such as shipbuilding, bridge construction, wind power, and automotive manufacturing.

This article explains what a hydraulic leveling machine is, how it works, its advantages, key components, applications, and maintenance tips, helping you understand why it is considered the backbone of precision sheet metal processing.

1. What Is a Hydraulic Leveling Machine?

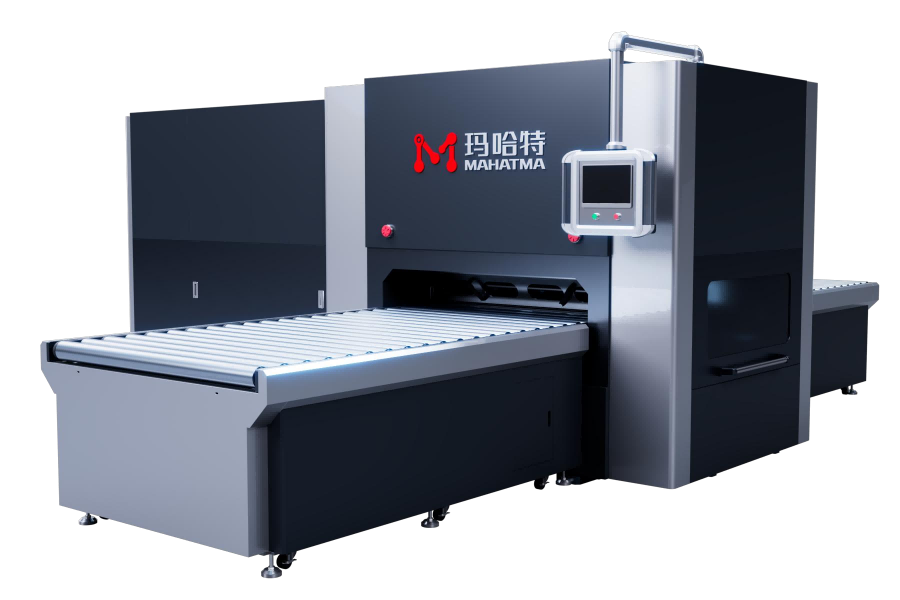

A hydraulic leveling machine is an industrial device used to correct the flatness of metal sheets or plates. It applies controlled mechanical pressure through a set of leveling rollers, driven by a hydraulic system, to eliminate internal stress, curvature, and surface unevenness.

Unlike traditional roller straighteners, a hydraulic leveling machine provides adjustable force, allowing operators to precisely control pressure and roller spacing according to different material thicknesses and strengths. This ensures high-accuracy flatness while minimizing material damage.

2. Working Principle of a Hydraulic Leveling Machine

The operation of a hydraulic leveling machine is based on the principle of reverse bending deformation. The sheet metal passes alternately over and under a series of work rollers. Each roller applies small, controlled bending stress, gradually removing internal strain and warpage.

Here’s how it works step by step:

Feeding the Material: The metal plate enters the leveling machine through the input rollers.

Progressive Bending: As the sheet passes through multiple upper and lower rollers, it undergoes repeated reverse bending.

Hydraulic Adjustment: The hydraulic cylinders adjust the roller pressure and spacing automatically, based on the material thickness and hardness.

Stress Elimination: The repeated bending and hydraulic pressure release internal stress within the metal structure.

Output of Flat Sheets: The output end delivers a perfectly flat and smooth plate, ready for cutting, welding, or coating.

This precision process guarantees that every metal sheet leaving the machine meets strict flatness standards.

3. Key Components of a Hydraulic Leveling Machine

A standard leveling machine includes several main components designed for reliability and accuracy:

Frame Structure: Provides overall rigidity to withstand bending forces.

Work Rollers: The core element that directly interacts with the metal sheet, arranged alternately in upper and lower positions.

Hydraulic System: Controls pressure adjustment and maintains consistent leveling force.

Drive Motor and Gear System: Provides power for roller rotation, ensuring uniform speed and torque.

Control Panel (CNC Optional): Enables precise adjustment of roller position, pressure, and leveling depth.

Support Bearings: Reduce friction and enhance machine stability.

The combination of these systems allows the hydraulic leveling machine to perform with both high speed and high accuracy, suitable for a wide range of materials from thin aluminum sheets to thick steel plates.

4. Advantages of Using a Hydraulic Leveling Machine

Modern manufacturing industries rely on hydraulic leveling machines for several reasons:

High Precision Flatness

Thanks to hydraulic control and fine roller adjustment, the machine can achieve flatness accuracy within microns, making it ideal for precision components.

Stress Relief

By eliminating internal stress, the machine prevents deformation during later cutting or welding, improving assembly quality.

Wide Range of Materials

Capable of processing carbon steel, stainless steel, aluminum, copper, and even high-strength alloy plates.

Automatic Control

CNC-controlled leveling machines allow operators to set pressure and roller positions digitally, reducing human error and increasing productivity.

Durability and Low Maintenance

Robust frame design and self-lubricating bearings ensure long-term stability and low maintenance cost.

Improved Production Efficiency

Fast leveling speed and automated adjustment make it suitable for mass production environments.

5. Applications of Hydraulic Leveling Machines

Hydraulic leveling machines are widely used in various industries that require precise sheet metal fabrication:

Shipbuilding Industry: For large steel plates used in hulls and decks, ensuring precise fit during assembly.

Wind Power Industry: Used to flatten thick plates for tower sections and turbine components.

Construction and Bridges: Improves structural accuracy and reduces on-site installation errors.

Automotive Manufacturing: Ensures even panel surfaces for car bodies and chassis components.

Steel Service Centers: Provides preprocessing of rolled steel plates before cutting or forming.

Aerospace and Heavy Machinery: Achieves tight tolerances required in precision engineering applications.

In all these fields, the leveling machine plays a vital role in ensuring the performance, durability, and appearance of finished products.

6. Maintenance Tips for Hydraulic Leveling Machines

To maintain consistent performance and extend the machine’s lifespan, regular maintenance is essential:

Lubricate Rollers and Bearings: Regular lubrication minimizes wear and keeps the rollers moving smoothly.

Check Hydraulic Oil Levels: Low or contaminated oil can affect pressure control and damage seals.

Inspect Roller Alignment: Misalignment may cause uneven leveling or surface scratches.

Clean Work Area: Dust and metal debris can enter moving parts, leading to premature wear.

Monitor System Pressure: Use sensors or gauges to ensure hydraulic pressure stays within the recommended range.

Schedule Preventive Maintenance: Periodic inspection by professionals helps identify early signs of component fatigue.

By following these simple steps, manufacturers can keep their hydraulic leveling machine in optimal condition, ensuring continuous and reliable production.

7. Choosing the Right Leveling Machine

When selecting a leveling machine, several factors should be considered:

Material Type and Thickness: Choose a model that matches your production material’s characteristics.

Leveling Width and Speed: Match the machine capacity with your sheet size and output rate.

Automation Level: CNC models offer higher precision but come with higher initial costs.

Manufacturer Reputation: Always select trusted leveling machine manufacturers known for reliable service and spare parts availability.

After-Sales Support: Ensure the supplier provides installation guidance, training, and long-term technical support.

8. The Future of Leveling Technology

As industries move toward automation and smart manufacturing, the future of leveling machines lies in intelligent control and digital monitoring. Modern systems now feature:

AI-based automatic adjustment of hydraulic pressure based on real-time feedback.

Integrated sensors to monitor plate stress and flatness in real time.

Predictive maintenance systems using IoT connectivity.

These advancements not only enhance accuracy but also reduce downtime and improve operational safety.

9. Conclusion

The hydraulic leveling machine represents one of the most critical technologies in modern metal processing. By combining hydraulic precision with mechanical reliability, it ensures that every sheet or plate meets the strictest standards of flatness and stress control.

Whether you are in heavy steel fabrication, automotive production, or metal service centers, a high-quality leveling machine is essential to improving efficiency, reducing waste, and achieving consistent production results.

As technology continues to evolve, hydraulic and CNC-controlled leveling machines will remain at the forefront of industrial innovation—delivering accuracy, speed, and reliability for the factories of tomorrow.