Laser cutting is a high-precision manufacturing technology that uses a focused laser beam to cut, engrave, or shape materials. It offers unparalleled accuracy and efficiency compared to traditional mechanical cutting methods. At its core, a laser beam melts, burns, or vaporizes material along a programmed path, producing clean edges and intricate designs. With the increasing demand for precision engineering and customized production, laser cutting has become a critical process in industries ranging from metal fabrication to decorative crafts.

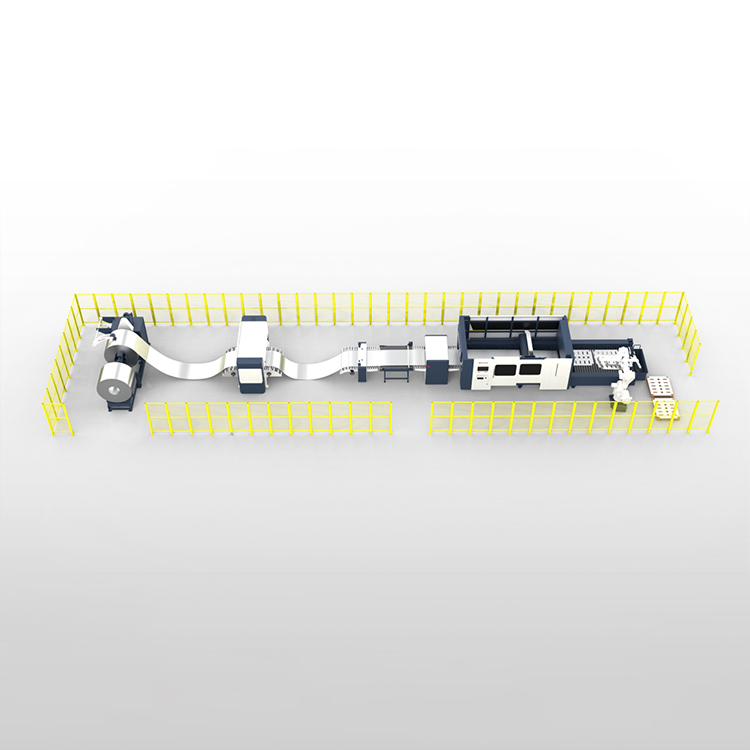

The T2 Laser Cutting Production Line is an advanced solution designed for both industrial and small-to-medium enterprises seeking laser cutting service with high productivity and precision. This system integrates powerful laser sources, automated feeding mechanisms, intelligent software controls, and specialized production platforms to deliver consistent results. It is suitable for various materials, including metals, acrylics, wood, plastics, and composite sheets.

Key Features and Professional Specifications

High-Power Laser Source

The T2 system uses a 1000–3000W fiber laser source, capable of cutting mild steel up to 20mm, stainless steel up to 15mm, and aluminum up to 10mm with precision tolerances of ±0.1mm. Fiber laser technology ensures high energy efficiency (>30%) and lower maintenance costs compared to traditional CO₂ lasers.Precision Cutting and Accuracy

With a positioning accuracy of ±0.03mm and repeatability of ±0.02mm, the T2 ensures high-quality cuts suitable for precision parts, decorative panels, and industrial components. The high-speed galvanometer scanning head allows cutting speeds of up to 30m/min on thin sheets, significantly increasing Production Efficiency.Versatile Material Compatibility

The T2 Laser Cutting Production Line supports both metal laser cutter applications and non-metal materials. Metals such as stainless steel, carbon steel, aluminum, copper, and brass can be processed efficiently. Non-metals like acrylic, wood, leather, and rubber are also compatible, making it an ideal solution for factories, makerspaces, and workshops.Automated and User-Friendly Operation

Equipped with an intelligent CNC control system and automated sheet loading/unloading, the T2 minimizes manual intervention. The integrated software supports CAD/CAM file formats, allowing users to import DXF, DWG, and AI files for seamless cutting. The system can operate continuously, enhancing production throughput.Production Features

The T2 line is especially suitable for cutting multi-element special-shaped workpieces, featuring multi-type cutting units in a single cutting figure. After uncoiling and leveling, the material enters the laser cutting unit and is fed to the cutting area through a specialized machine structure. The integrated cutting and sorting platform transmits the cut material to the blanking platform for organized sorting. Additionally, the rolling platform feed and cut mechanism ensures smooth material flow, while high-precision CNC leveling and high-speed continuous cutting guarantee accuracy and efficiency even for complex geometries.Space-Saving and Desktop Options

For smaller workshops or educational environments, the desktop laser cutter variant of the T2 series offers a compact footprint while maintaining high precision. Its design emphasizes safety with enclosed cutting chambers and fume extraction systems, making it suitable for schools, labs, and small businesses.Energy Efficiency and Cost Savings

Fiber laser technology ensures lower energy consumption than traditional methods, and the T2 system’s modular design allows selective operation of laser modules to optimize power usage. Operators can achieve high productivity without significantly increasing operating costs.

Applications and Use Cases

The T2 Laser Cutting Production Line serves a wide range of industries:

Metal Fabrication: Cutting stainless steel, carbon steel, aluminum, and copper for machinery parts, automotive components, and industrial equipment.

Signage and Advertising: Creating intricate acrylic signs, LED panels, and decorative metal logos.

Furniture and Interior Design: Cutting wooden panels, MDF sheets, and metal decorative elements for high-end furniture.

Electronics and Precision Components: Manufacturing metal enclosures, brackets, and customized components with tight tolerances.

DIY and Educational Projects: Desktop variants allow hobbyists and students to explore creative designs, from miniature models to custom jewelry.

By offering both laser cutting service and direct equipment solutions, the T2 line allows companies to scale production efficiently and diversify their offerings. Its specialized production features, including multi-element cutting units, rolling platform feed, CNC leveling, and integrated cutting and sorting, make it an ideal choice for both high-volume industrial operations and precision custom work.

Maintenance and Best Practices

To ensure optimal performance and longevity, regular maintenance is essential:

Optics and Laser Source: Clean lenses and mirrors every 100–200 hours of operation to maintain beam quality. Inspect fiber connections to avoid energy loss.

Cooling System: Ensure the water chiller or closed-loop cooling system operates at recommended temperatures (20–25°C). Regularly replace the coolant to prevent corrosion and overheating.

Mechanical Components: Lubricate linear guides, ball screws, and moving parts every 500 hours of operation to reduce friction and wear.

Exhaust and Filtration: Clean filters and exhaust ducts weekly to prevent dust accumulation, ensuring clean cuts and safe operation.

Software Updates and Calibration: Update the CNC control software regularly and calibrate the system to maintain cutting precision.

Conclusion

The T2 Laser Cutting Production Line represents the forefront of laser cutting technology, combining high power, precision, and versatility. From industrial metal laser cutter applications to creative desktop laser cutter projects, it provides an efficient, reliable, and scalable solution for modern manufacturing and design. Its advanced production features, including multi-element cutting, rolling platform feed, CNC leveling, and high-speed continuous cutting, enable both large-scale industrial operations and precision custom work.

Whether you are seeking a laser cutting service for prototyping or looking to integrate a T2 line into your production workflow, this system offers the precision, speed, and adaptability required to meet today’s industrial and creative demands.