What Is a Level Machine?

A level machine, also known as a hydraulic leveling machine, is industrial equipment designed to straighten, flatten, or level metal sheets, plates, and other materials. By using hydraulic pressure, rollers, and precise adjustment mechanisms, the machine corrects distortions, residual stresses, and uneven surfaces caused during metal processing, cutting, or welding. Level machines are essential in metal fabrication, construction, automotive, and manufacturing industries, where flatness and precision are critical for subsequent processing or assembly.

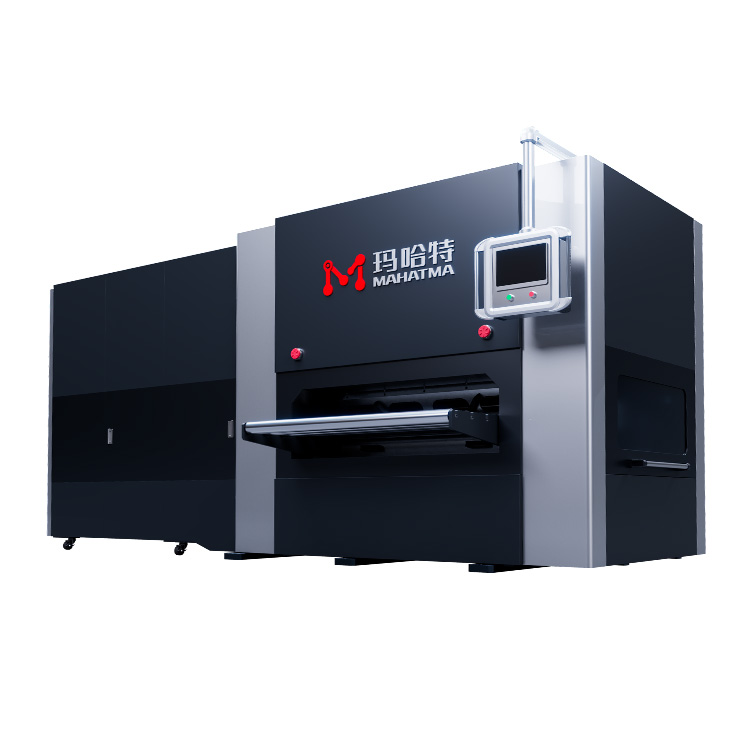

The hydraulic leveling process provides consistent results with high precision, reducing material waste and enhancing productivity. Modern level machines, such as the MHTR30, feature CNC control systems, adjustable roller spacing, and advanced hydraulic pressure management, allowing operators to achieve flatness tolerances of ±0.1–0.2 mm for sheet metal up to several meters wide.

Key Features of a Level Machine (with Professional Data)

High Precision Flattening

Level machines can achieve flatness accuracy of ±0.1 mm on steel or aluminum plates.

Hydraulic rollers apply uniform pressure across the sheet, ensuring consistent straightening without compromising material integrity.

CNC-controlled models allow programmable roller passes, improving repeatability and reducing operator error.

Hydraulic Pressure Control

Modern hydraulic level machines typically provide pressure ranges from 50 MPa to 200 MPa, adjustable to different material thicknesses and hardness.

Precise pressure control minimizes surface deformation and prevents scratches or dents, ensuring high-quality output.

Versatility in Material Types

Suitable for various metals including stainless steel, mild steel, aluminum, copper, and brass.

Can handle sheets from 0.5 mm up to 30 mm thickness and widths up to 2000–3000 mm, depending on the machine model.

Automation and Ease of Operation

CNC hydraulic leveling machines feature automatic leveling sequences and programmable roller paths, reducing manual intervention.

Operators only need to set material parameters, and the machine automatically adjusts rollers and hydraulic pressure to achieve the desired flatness.

Durability and Heavy-Duty Construction

Frame structures are typically made of high-strength steel and reinforced with stress-tested welds, providing long-term stability.

Rollers are coated or hardened to HRC 55–60, resisting wear even under continuous operation.

Time and Cost Efficiency

Compared to manual flattening or hammering, hydraulic level machines can process a sheet in 3–10 minutes, depending on thickness and size.

Reduces scrap rate by up to 15–20%, saving materials and improving production efficiency.

Applications of a Level Machine

Metal Fabrication Industry

Corrects warped or bent metal sheets before cutting, stamping, or welding.

Ensures precise assembly in automotive panels, appliance parts, and machinery components.

Construction and Structural Engineering

Used for flattening steel plates for beams, roofing, and bridge components.

Guarantees flat surfaces for welding and assembly, reducing structural defects.

Automotive and Aerospace Manufacturing

Maintains strict flatness tolerances for body panels, chassis components, and aerospace sheet metals.

Ensures proper alignment during painting, coating, or assembly.

Shipbuilding and Heavy Equipment

Leveling large steel plates used in ship hulls or heavy machinery.

Reduces distortion caused by previous cutting or transportation.

Small Workshops and Fabrication Shops

Compact hydraulic leveling machines allow small manufacturers to process metal sheets efficiently with minimal manpower.

How to Use a Level Machine

Material Preparation

Inspect sheets for oil, rust, or dirt. Clean the surface to ensure smooth operation.

Measure thickness and dimensions to adjust roller spacing and hydraulic pressure.

Machine Setup

Adjust hydraulic pressure according to sheet thickness (e.g., 100 MPa for 10 mm mild steel).

Set roller gap and number of passes based on material type and desired flatness.

Feeding the Material

Feed the sheet slowly into the rollers, ensuring even alignment.

For large sheets, use auxiliary support tables or rollers to prevent sagging.

Leveling Process

Engage hydraulic rollers gradually. CNC machines will automatically adjust pressure along the sheet length.

Monitor the sheet for any signs of deformation or roller misalignment.

Inspection

After processing, use laser flatness measurement tools or straight edges to verify flatness.

Repeat passes if necessary to achieve target tolerance.

Maintenance of a Level Machine

Regular Cleaning

Keep rollers and machine bed free of dust, debris, and metal shavings.

Wipe with a clean cloth and apply a thin layer of protective oil to prevent rust.

Hydraulic System Maintenance

Check hydraulic oil levels and quality every 3–6 months.

Replace oil filters and inspect hoses for wear or leakage.

Maintain oil temperature within recommended range (20–60°C) to ensure consistent pressure.

Roller and Mechanical Component Inspection

Inspect roller surfaces for scratches or dents.

Ensure all bearings and moving parts are lubricated and free from vibration.

Calibration and Safety Checks

Periodically calibrate CNC controls and pressure gauges.

Test emergency stops and safety interlocks before each shift.

Operator Training

Ensure operators are trained in both hydraulic and CNC control operations.

Proper training reduces accidents, material waste, and machine downtime.

Conclusion

Hydraulic level machines are indispensable in modern metalworking and fabrication industries, offering precision, efficiency, and versatility. They correct warped or bent metal sheets, ensure flatness tolerances as tight as ±0.1 mm, and reduce material waste significantly. Proper use, regular maintenance, and operator training are critical to maintaining performance, longevity, and safety.

Whether for large industrial plants, automotive production, or small workshops, hydraulic level machines like the MHTR30 ensure reliable, high-quality results, improving overall productivity and product quality.