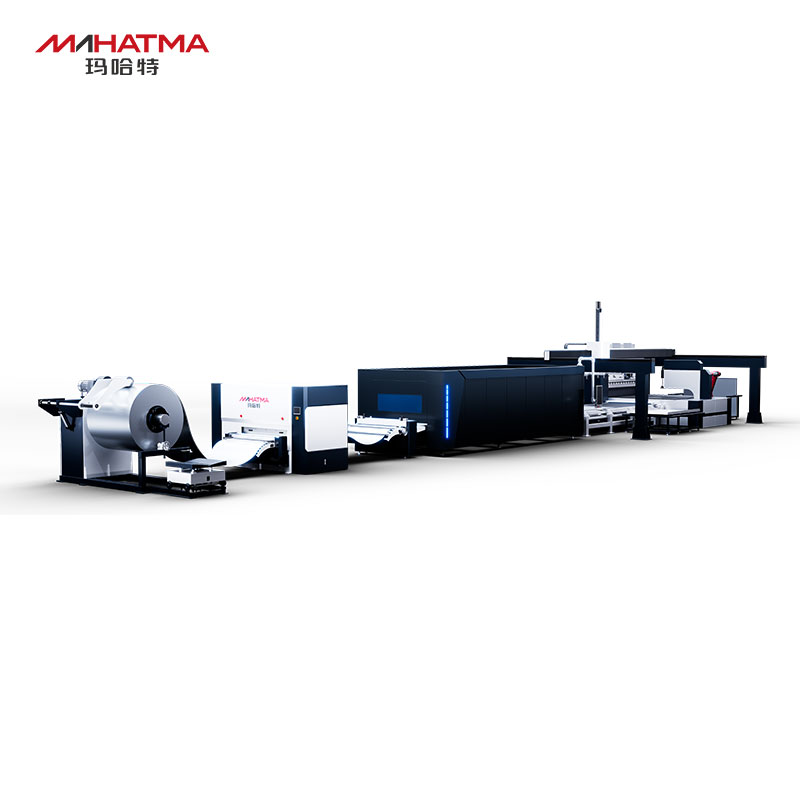

July 2025, Dongguan — Against the backdrop of the ongoing "Industry 4.0" and "Smart Manufacturing China" strategies, Mahatma (MAHAT) once again leads the industry with technological innovation, officially launching its new-generation uncoiling-leveling-laser blanking production line, injecting new momentum of efficiency, intelligence, and flexibility into the metal Sheet Processing sector.

The Mahatma Uncoiling-Leveling-Laser blanking line integrates automatic uncoiling, Precision Leveling, high-speed laser cutting, intelligent nesting, and automatic material collection, breaking through the bottlenecks of traditional stamping, shearing, and standalone laser cutting. It achieves one-stop processing from coil to finished product. The production line covers a thickness range of 0.1mm to 25mm, including five series: UL (Ultra-Thin), TL (Thin Plate), ML (Medium-Thick), HL (Heavy Plate), and XL (Ultra-Thick), making it widely applicable to industries such as automotive manufacturing, construction machinery, home appliances, electrical cabinets, rail transit equipment, shipbuilding, heavy industry, and photovoltaic new energy.

Compared to traditional production lines, the Mahatma Laser Blanking Line achieves a qualitative leap in automation and processing efficiency:

Cycle time improved by over 45%: One-touch operation for loading, leveling, cutting, and blanking, significantly reducing intermediate transfers and manual intervention.

Material utilization increased by 7%: AI intelligent nesting technology effectively controls raw material loss, reducing it to less than 4%.

Labor costs reduced by 60%: Flexible production line controlled by a single operator, enabling rapid switching between multiple batches and specifications.

Precision control of ±0.02mm/m: High-precision laser positioning and patented leveling technology ensure product consistency and stability.

Mahatma’s independently developed "Smart Super Leveling Technology" is a global first, utilizing laser 3D detection and image processing algorithms to achieve real-time leveling precision adjustment and automatic deviation correction. It adapts to various sheet materials (steel, aluminum, copper, titanium, etc.) and thickness requirements, completing sheet pretreatment in seconds.

Additionally, the production line supports seamless integration with MES/ERP systems and offers optional modules such as automatic stacking, vision recognition, AGV transfer, and spray coding, building a truly smart and flexible factory.

Currently, Mahatma’s laser production line has been successfully deployed in industries such as automotive manufacturing, new energy, smart home appliances, and construction machinery.

For example, a Jiangsu-based automotive manufacturer adopted the TL series + MES system, achieving not only high-efficiency cutting for subframes and battery tray components but also a successful transition from traditional processing to digital manufacturing.

Mahatma adheres to a "domestic sales + foreign trade" dual-drive strategy, with its marketing and service network spanning over 100 countries and regions. It has professional sales and service teams in the U.S., Japan, Germany, Canada, Southeast Asia, and the Middle East, providing localized and responsive technical support to global customers.

"We don’t just provide equipment—we deliver systematic solutions for productivity, cost optimization, and competitiveness enhancement," said a Mahatma marketing executive.

Looking ahead, Mahatma will continue to increase investment in smart manufacturing, advancing leveling and cutting technology upgrades and building a smart processing ecosystem that adapts to a wider range of industries and scenarios. This will empower global manufacturing to embrace a new era of flexibility, high precision, and green intelligence.