In high-end commercial complexes, airport hubs, and other landmark buildings, the flatness of aluminum curtain walls directly impacts both the aesthetic value of the structure and the integrity of its weather sealing. However, residual stress from the rolling process and thermal deformation during cutting often lead to defects such as wavy edges, center buckling, and S-shaped warping, which traditional leveling methods struggle to address. These issues not only disrupt light reflection effects but may also cause joint leakage and improper installation.

Precision leveling machines, with their multi-roller systems and exact pressure control, have become critical equipment for curtain wall manufacturers tackling flatness challenges. Waviness and warping in aluminum panels are long-standing industry-wide problems. After installation, even a flatness deviation exceeding 0.5mm becomes visibly apparent under sunlight, creating unsightly wave-like shadows—especially on hybrid glass-aluminum facades. Moreover, forcing warped panels into place results in uneven seams and insufficient gasket compression, leading to water infiltration during heavy rain and costly repairs.

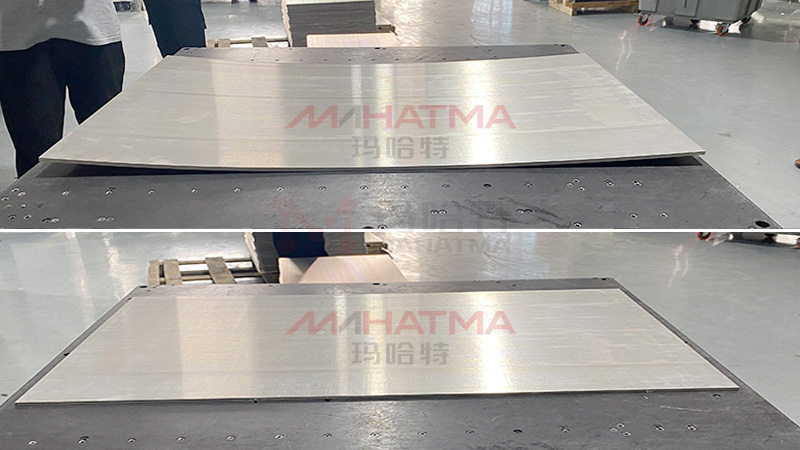

To solve these challenges, Mahatma Precision Leveling Machines employ an 18+ roller multi-stage progressive leveling system and real-time shape monitoring to redefine flatness standards for curtain wall panels. With high-density roller configuration, 23 leveling rollers apply micro-stress stretching at 0.1mm precision to eliminate internal rolling stresses. Our proprietary Smart Over-Leveling Technology presets a reverse camber (0.05°–0.2°) based on the spacing and installation method of curtain wall mullions, counteracting post-installation stress deformation. It also features edge-stress elimination to resolve "lotus leaf edge" defects from cutting, ensuring long-edge straightness within <1mm/2m.

Say goodbye to "wavy façades"—Mahatma Precision Leveling redefines wall quality!